We know now that we will be driving the six cheese

pumps on our cheese fountain with one motor, but what's the best way to drive them? The design we are planning has the six pumps arranged in a hexagonal lay-out with the drive pulleys on top. That means that the drive motor will need to be mounted at the top as well. My first choice for a motor was a 1/2HP Harbor Freight submersible pump that I happened to have on hand, but after running it outside of water for ten minutes it was blazing hot! I also had a fractional horsepower motor that is not only DC but also has a variable speed rheostat, so if we don't need the entire 1650RPM's we can turn her down a bit.

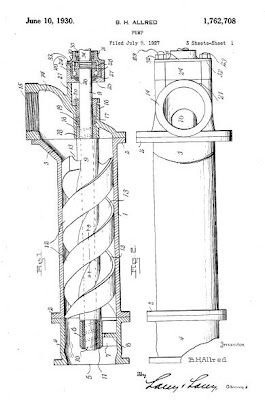

If the motor is mounted with the arbor pointed towards the ceiling the arbor will turn counter-clockwise. Out plan is to use a single drive belt routed as shown in figure

1.

With this lay-out the augers will need to be made to be driven clockwise, so this is what we did.

After assembling the pumps we realized that there was going to be a bit more friction working against us even before we add the congealing cheese, so we decided that we needed to switch from a single drive belt to three. Besides the advantage that the belts would contact more of each of the pulley's diameter, if for some reason one of the pumps would act-up we can always yank the belt and still have four pumps going. So we decided on the belt layout shown in figure

2.

Oops! That won't work! With that belt lay-out the pump pulleys will be driven counter-clockwise, and the augers are already made to turn clock-wise. Well, we could mount the motor with the motor shaft pointing at the floor, but that would require a total rebuild of the fountain, which is already well underway, so it looks like we're going to punt.

Let me explain the belt we're using. Many, many years ago I repaired clocks, and my watchmakers lathes were powered be a round rubber belt. These belts were awesome. If a belt broke or needed to be replaced you simply cut the length you needed from a spool and using the alcohol lamp I had on my bench the ends were melted and touched together. A few minutes pass and the belt is ready to run. This is just the kind of belt we need. It's off to eBay and after a few attempts to remember the proper name of the belt we discovered this

BELT. (That's a link, son)

The belt we purchased was 3/16" and was .99 per foot. We purchased 15 feet, which will yield us four belts. We only need three but hey, you never know.

So, with this style of belt we can do something special; we can twist the belt as shown in figure

3.

This will allow us to run the pumps in a clockwise rotation with a pump pulley that is

running counter-clockwise.

This pattern came to mind over a bacon, egg and CHEESE biscuit (sandwich) at Carter Brothers BBQ in High Point NC with Seth and his Best Man Josh. Is there any problem that bacon and cheese can't solve?

Now we need to make some pulleys.

A few months back my son Seth announced that he was planning on having a six-cheese nacho cheese fountain at his wedding, just like the one in the movie Talladega Nights: The Ballad of Ricky Bobby. It was a few weeks ago when I learned that "we" would be making the fountain!

A few months back my son Seth announced that he was planning on having a six-cheese nacho cheese fountain at his wedding, just like the one in the movie Talladega Nights: The Ballad of Ricky Bobby. It was a few weeks ago when I learned that "we" would be making the fountain!